A North American fruit sauce producer faced major production setbacks due to splashing and sealing issues during hot filling. Waldner North America stepped in with a customized solution that transformed the company’s process, boosted output and restored product integrity.

Fruit sauces are a hit—especially with kids. From apple and mango to banana and pineapple, these convenient, single-serve snacks are a staple on grocery shelves and in school backpacks. While their ingredient lists may appear simple, the process of packaging fruit sauces requires careful precision. Accurate filling and sealing are critical to ensuring product integrity, food safety and shelf stability—making advanced, reliable packaging solutions essential to success.

A leading fruit sauce manufacturer in North America recently faced significant challenges in their packaging line, particularly when filling and sealing its product into cups. Frequent splashing compromised the whole packaging process, slowed production and ultimately constrained revenue growth. That’s when the company called in the experts at Waldner North America (WNA).

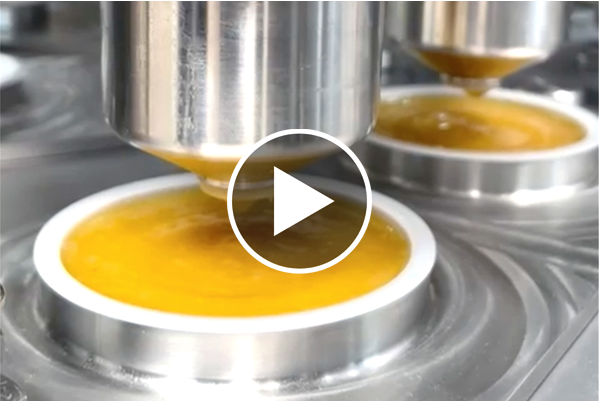

“It was clear they were relying on an outdated machine that could no longer meet the scale and complexity of their operations,” explained Matt Gwin, product manager at WNA. “We identified poor nozzle control as a key issue, causing sugary sauce to drip and splash, contaminating lids and carrier plates and interfering with the seal. In some cases, fruit fibers would land on the seal area, leading to faulty seals that eventually developed small leaks, leading to spoilage and putting the product safety at risk.”

Compounding the issue was the high temperature of the product during hot filling, which made the juice more fluid and prone to splashing and overflowing. The resulting steam also created challenges for achieving a reliable seal, especially critical for a sensitive product like fruit sauce. Heat buildup increased pressure within the cups, raising the risk of burst seals if filling wasn’t precisely controlled.

Waldner teams in Germany and the U.S. collaborated to develop a custom-built solution tailored to the product’s specific characteristics. Through extensive testing, the team fine-tuned the machine to deliver clean, accurate fills. One key adaptation was the implementation of a bottom-up filling approach, where the cups are raised to the nozzle rather than having the sauce dropped from above. This prevented splashing and product waste while ensuring reliable seal.

“We have extensive experience in managing hot-fill applications,” Gwin added. “Our new solution addressed both the temperature and sealing issues. It also features a sophisticated lane-by-lane data-coding system to identify and trace anomalies like splashes or bad seals, helping streamline troubleshooting and minimize waste.”

The new, compact 5-lane filling machine boosted production efficiency, with the system now producing 150-200 cups per minute (9,000-12,000 cups per hour) from a space-saving 1.5 m x 1.9 m (2.85 m2) footprint, all while reducing downtime and improving product quality.

“As important as operating a robust, reliable machine is having a partner who offers excellent customer service and preventative maintenance. With the right support, manufacturers can stay ahead of breakdowns and avoid production slowdowns altogether,” Gwin concluded.

Want to learn more about Waldner’s filling and sealing solutions for fruit sauces and other sensitive products? Click here to contact WNA’s team.

For more information, please contact: