Pouch packaging is one of the most common and desirable packaging solutions. We have seen especially strong growth with stand-up pouches. Thanks to the pouch formats versatility, they have made a mark in almost every single food segment, including dairy products, beverages, ready-to-eat meals, pet food and treats, produce, snack foods, and many others. Depending on product type, application and other customizable attributes, pouches are available in a variety of formats including flat bottom pouches, gusseted pouches, spouted pouches, zipper pouches, and many more.

Well-designed pouches are vital for maintaining the quality of finished products. Pouches can be made of one or more layers of plastic film, aluminum foil, sealant, and other materials depending on product type and shelf-life requirements. Package shape and functionality greatly affect product value. Matching a product with the appropriate type of packaging that is easy and practical at the point of use is key in launching a successful product.

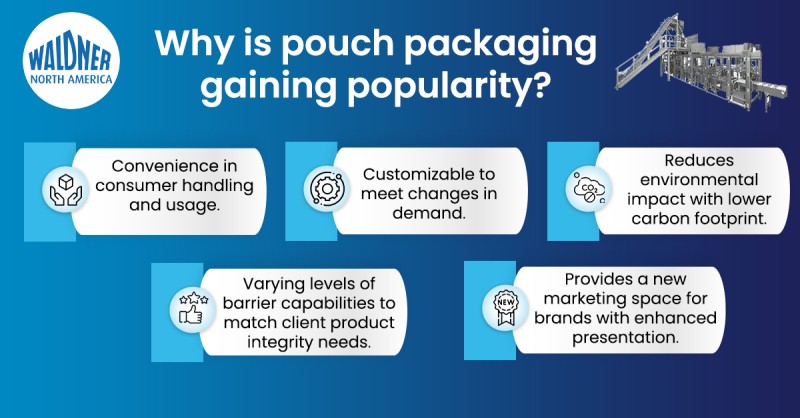

Benefits associated with pouch packaging

1.

Convenience in handling: Convenience and ease of use are the primary drivers for consumers these days. For example, creating pouches that allow liquid products to be microwaved or including a seal tab or zipper for further use of dry products.

2.

Immense scope for customization: Since the shape, size and material of the pouches can be customized as per specifications, pouches are considered to be highly flexible and adaptable. This ability gives pouch packaging manufacturers a broader customer base for pouch supply.

3.

Reduces environmental impact: Lower carbon footprint. Recent studies have made it clear; the non-recyclable pouch format produces a lower carbon footprint than its recyclable glass and metal container cousins. This is principally owing to a vastly reduced transportation carbon load, and a relatively low carbon load on a per unit production. With new fully recyclable and biodegradable pouches the environmental advantages are exponential. If you’re interested in making an environmental impact and not just green washing, modern pouches offer dynamic advantages in comparison to metal and glass containers.

4.

Ensure product protection: Pouch packaging prevents products from degradation, similar to a can or glass jar, since its multiple layers of material can survive extreme environmental conditions. This not only increases shelf life but also maintains the product quality for the desired period.

5.

Ensure brand promotion: Pouches provide a new marketing space for brands. The appearance of products is enhanced due to the use of modern flexographic printing techniques

Overview of Waldner DOSOMAT Pouch Filling & Sealing Technology

The Waldner DOSOMAT Rotary and Inline Pouch systems offer both low and high output solutions for a variety of pouch filling applications. Each stage of this process insures extremely efficient control and handling of the pouches through the desired filling stations and the ultrasonic sealing station for hermetic closure. For spouted pouches, Waldner offers three solutions for filling, sealing, and capping these unique packages:

- Seal the spout in the pouch, fill through the spout, and then apply the cap closure

- Fill through pouch centre spout and apply cap closure

- Corner spouted pouch: fill through top opening of pouch and seal

Benefits of a DOSOMAT:

- High output, high uptime, high quality – Highest OEE

- Exceptional finished pouch presentation

- Lower cost per package out-the-door

- Lower Total Cost of Ownership

Pouch handling system

- Complete pouch control with servo driven pouch loading, opening, closing, & discharge

- All critical functions operate in stationary mode

- Innovative pouch clamping system design

- Concurrent pouch opening: inward motion of clamping system, top and bottom suction cups on both sides, and air blast